Hello, and welcome back to The 8-Bit Guy.

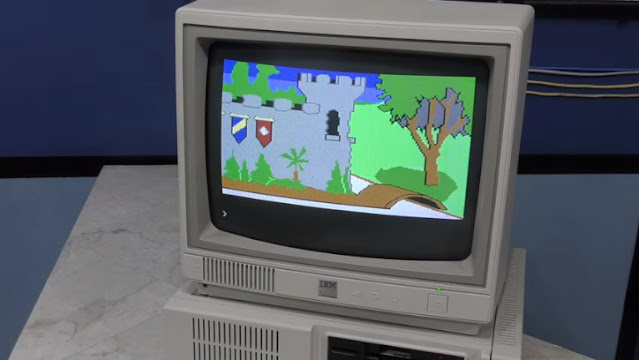

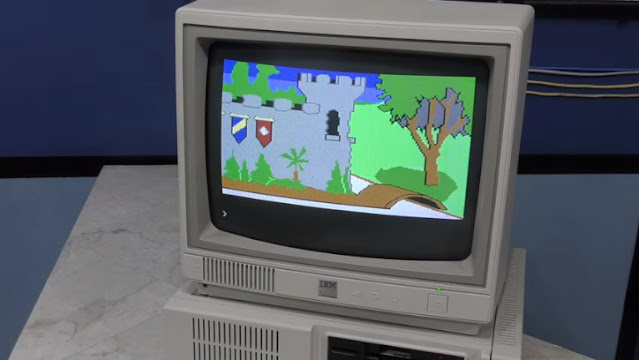

So, during this episode, what I ’m getting to be doing may be a complete restoration of this IBM PC jr.

Now, this was recently donated to me by Sean Hafeez, and it ’s actually not in bad shape, but it actually does have a drag with the monitor and therefore the keyboard. So, let ’s see what we will do to repair it up!

Looking at this technique, cosmetically it's in pretty fine condition and just needs some minor cleaning. But the keyboard is noticeably yellowed compared to the pc. It also has some nasty gunk between the keys, which shouldn't be too hard to wash, but it's also missing the small silver badge.

The monitor may be a different story. As seen here within the original unboxing video, the monitor doesn't work, albeit it had been working before Sean shipped it. Since the PCjr features a proprietary video connector, there was no easy thanks to test This monitor on another system, so I plugged during a composite monitor to the PCjr to verify the pc was working. Then, I took the monitor partially apart to seem for love or money loose, but couldn't find anything. Eventually, I discovered That if I whacked the side of the monitor, it might come on for a brief time, but the image was unstable.

So we'll come to the monitor later. For the instant, let's have a glance at the keyboard. This thing features a lot of black scuffs optically, some that don't show up well on camera.

So, I'm getting to use one among my tried and true methods, where I just put some bicarbonate of soda on a towel then wet it with water until it becomes quite a mushy paste. This works extremely effectively on this keyboard. Here's one On the side that wouldn't come off easily with Windex or alcohol. And it just wipes away in seconds with bicarbonate of soda. Once I'm proud of the outside, I made a decision I should open it up, for variety of reasons For one, it'll make it easier to wash the keys, but also I would like to retro rite this thing.

While removing the screws on rock bottom, I also noticed that it's these little rubber feet here, and one there, but It's missing this one. So I will be able to need to find or fabricate a replacement.

Despite removing all of the screws, I couldn’t get the keyboard open.

Feeling around on this label, it felt like maybe there was a hidden screw under there. And surely, there it's. After removing that, it opened easily, and oops . I forgot to require the batteries out of this thing.

Ok, here's The circuit card, and here's the small rubber contact mat, which appears to also double as a spring for every key. This thing is pretty filthy and can got to be cleaned up as well!

I wasn't sure how the keys came out initially. seems like the key comes out easily enough, as does the enter key. It appears the keys just pop off with some force like this. So, I assumed maybe I should get out my And while that does work, it occurred to me that it'd be easier just to push them out from the opposite side. Which works fine too.

OK, so this is often a touch little bit of a mystery before I start the retro rite. If you check out the particular PC junior's case color and compared to mention, this key, the color matches perfectly already. I see no reason to aim to treat these keys in the least. But, once you compare to the keyboard case itself, the keyboard is noticeably more yellow than the pc . I feel it's going to be less visible on camera, but there's clearly a difference face to face.

But here's where things get interesting. The within of the keyboard is actually an equivalent color because the outside. This typically indicates that this might be the first color of the keyboard because UV light damage will usually just affect the surface. So, I'm but I do know I would like to require some alcohol and take away the residual adhesive from this tiny badge area here, because I decide to fabricate a replacement badge. And it's like alcohol did the work for that. Now, all of the keys on this thing are dirty, but 4 or 5 of them have this really sticky gunk on them like this. I attempted using Windex, and later alcohol and neither one made a dent.

However, I found that I could use my fingernail to carefully scrape the gunk off. Then, alcohol removed what residue was left. And this is often the finished key. So, now just to try to to the remainder of the keyboard. Since the keyboard is fairly small, and to avoid any streaking, I made a decision to use the submersion method thereby. I filled up a little bucket of water, just deep enough for the keyboard. And one concern I had was that the rear of the keyboard had tons of air pockets and I wasn't sure if it might sink or not. Fortunately, it did. I'll be using the clear salon developer liquid. Then I'll let this sit call at the sun for a couple of hours. And while that's going, I assumed I'd turn attention to the monitor problem.

OK, so, for the CRT a part of this problem, I assumed I might enlist some help. So, I do know my way around a CRT a touch bit, I've done videos on CRTs before, but I'm by no means an expert, then I assumed I might ask DJ here, who lives in town, he also runs a YouTube channel doing all types of old retro computer junk too, so I'll put a link down within the description. Anyway, he knows a touch more about CRTs than I do so he's getting to help me out with

this.

Hey y'all, I'm DJ and I'm not an expert with monitors either but I've had tons of experience with them over the years and I've learned tons from one among the fashionable experts in CRTs. And there's only a couple of things that are probably wrong with this thing given what it's doing immediately. And therefore the one thing that I feel we're probably watching here are some things to try to to with the fly back transformer. This monitor was working before it And typically what this suggests is that the fly back transformer, which may be a big heavy part mounted on top of a PCB probably had some rough handling of the whole monitor during the shipping. It's a miracle lately that you simply can ship a CRT and have it arrive in one piece.

But, thereupon fly back transformer getting jostled around it's quite possible that it's broken solder joints or possibly cracked a trace on the PCB then, what we actually got to do is simply quite open it up and see what we're working with and see if So, DJ need to work disassembling the monitor. Of course, I had already done this myself but hadn't gone any deeper than simply taking the duvet off. So, let's turn it on here and see what happens.

Hey! We got high voltage! So, we already knew that that was intermittent. But, what I wanted to show it on for was to see and see if we could tell that the heater was glowing. And that I do see the heater glowing Just faintly. I actually had to show the lights call at the space and make it completely dark before the camera was ready to really see the heater glowing.

Well, that tells us that the heater isn't the matter. I just wanted to ascertain if the heater was getting to come on, but we got high voltage this point, so something changed regarding the orientation of the machine, or us banging around substances trying to urge it disassembled. All right, so once we had it face down and that we were performing on it, we noticed it had been turning on every single time that we tried to show it on and had an image whenever.

And then, we flipped it right down to this orientation and it stopped having any high voltage. If I turn it on at now, it quite goes whit, but it doesn't make any high voltage. But, if I flex the board, it comes on. Then I think we've got either a nasty solder joint or a broken trace. So, albeit I don't think this thing is charged any high voltage, I would like to form sure the tube is discharged before we fiddle So I will be able to hook onto the DAG ground there. So this screwdriver is now grounded.

And that we just catch on up under the cup. And there was no curpaps. So, it's not charged After manufacturing that they had placed an enormous blob of what seems like some quite silicone like they use for windshield sealant. During manufacturing that they had placed an enormous blob of what seems like some quite silicone like they use for windshield sealant.

Anyway, we couldn't catch on loose so DJ just sliced ??it off together with his knife. Fin ally, we had all of the board disconnected.

OK, so we noticed this from the opposite side as we were disassembling it and that we suspected that there was a crack, but here may be a big ole crack that goes clear over to here. And it cuts, it possibly cuts through this trace , definitely cuts through this trace cuts all the way across this solder joint, then there's this gap here, an air gap for this transistor, but on the opposite side of it, it continues across here and cuts through this trace, and possibly this trace And perhaps into this one.

So, we just got to investigate that and see what we'd like to bridge out there. Since this crack could be hard to ascertain for a few of you, I assumed I'd get the hand glass out and allow you to see a touch more close-up what we're handling here. And that I created this tiny diagram so you'll see exactly where the crack is and the way much of the board it covers. As bad as this looks. , it doesn't actually cross that a lot of traces so, this might are tons worse.

OK, therefore the first two that we're getting to tackle are this one right here, which we will actually, if you get into it with the hand glass you'll see that there's a crack throughout the center of that hole, but all We'd like to try to to is reflow that joint to form it whole. This one here, though, we'd like to urge in here and scrape away a number of the solder mask on either side of this crack, in order that I just want to show enough copper here that we will do this bridge. Next, DJ added a touch solder to the copper he had exposed, then he bent a paperclip to an approximate size and soldered it right across the crack. Then he just chopped off the additional fastener, and therefore the joint is repaired.

OK, so then I just want to form sure that this joint that we just made has continuity so I'll go here and therefore the meter says yes. Then, we worked to re-assemble the monitor, which took about 20 minutes. We also used some hot glue to fill subsequently area we had to chop away before. Well, let's See if we let the rout out or if it blows up or something like that. We've got it all replace together again. Hoping for the simplest.

Hey, I hear high voltage. Check out that!

I ’m getting to nudge it now. Still got high voltage. Alright!

I ’m calling that one fixed!

OK, it's been a couple of hours, so time to see on the keyboard! I've need to admit I can't see any difference, but it's hard to mention until I rinse it off and take it inside to match with the PCjr So here it's after rinsing and comparing it with the opposite half the keyboard, I can't actually see any color difference. So, I feel this is often the first color in any case. That being the case, it's time to place the Keys back in. Fortunately, I do have an image I took of the keyboard before I started, which can make it easier to re-assemble. Popping keys back to a freshly cleaned keyboard is usually extremely satisfying. It's such as you just bicycled up a very tall hill and now you're coasting backtrack the opposite side. And here's the freshly cleaned rubber mat. And therefore the logic board. And therefore the back piece.

And here ’s the finished keyboard. The color might not have changed, but it's 100 times cleaner now!

It looks almost fresh, apart from one problem, which is that missing badge. So I had a thought of the way to solve this. Watching the PCjr itself, I assumed the badge probably matched this one. They're an equivalent size. feel I can use my brother label maker to print a replacement. I always keep several different colors available for this type of thing. I feel I'll use the black text on clear background. So, I'll pop this one into the label maker, then I made a fast little design here. Since the labels aren't wide enough, I made it as two separate parts. And now to print it.

Of course to form this look right, I would like to stay the labels onto this aluminum tape. So I first had to chop a square that fit perfectly within the hole. And once I used to be sure it fit, then I peeled the backing off the label like so, and that I think you'll see where I'm going with this. I just stuck this right to the aluminum. And here's the finished badge. Granted, this is often much thinner than the first badge. But I feel it'll still get up to scrutiny in most cases. And there we've it. It' obviously not perfect, but it had been easy to form and that I would imagine the typical person would never notice that it wasn't the first. I visited the ironmongery shop to seek out rubber feet, but it's hard to understand which one will fit.

As I'm always needing rubber feet in various sizes and I'm almost out of them anyway, I just bought one among each package. I'll likely use these at some point within the coming years. This keyboard uses unusually small rubber feet I attempted the littlest one I got and it had been still overlarge. What I'll do is order some smaller ones on eBay, except for the instant I can just cut these right down to size and that they should fit just fine. yeah, there you go. Fits fine now.

However, there's still a drag therein the new foot is slightly taller than the remainder, especially this one on the other end. So what I'll do is plow ahead and pull that one out too, and replace it with another of an equivalent kind . then I'll turn it over and test it out. Yep, it's not wobbly anymore. As for the pc, it still needed to be cleaned, but it had been mostly just scuffs and dirt, so I just used my usual methods to I used some alcohol and cleaned the disc drive heads. This one is double sided, so you've got to Then I used some lithium grease on all of the moving parts, especially the rails. And now it's time for a final test. The pc looks good. And it appears to be working properly also. This restoration project has been an entire success, unlike a number of my earlier projects.

All right guys, I hope you enjoyed this episode on restoring the PC Junior. This is often one among my more successful restoration projects. And that I always want to offer a thanks bent DJ for helping me with this monitor. There's something that I would Like to say, though. First of all, this video wasn't planned, I just needed to urge it done because I'm planning on doing a whole documentary on the PC Junior here relatively soon. So, I just needed to urge it working. the opposite thing that I wanted to say is because I'm projects a CRT display during this video, I just thought this is able to be an honest opportunity to say a drag that pops up from time to time. I always get comments down in my videos saying, “Hey David, can't you remove that terrible high pitched whine noise that I hear, it hurts my ears.” Well, here's the thing. Actually, I do.

In fact, 95% of the time I buy that whine removed, but 5% of the time I don't. And you're hearing the five hundred of the time that I've missed it. The rationale I missed it's because my 42 year old ears simply can't hear the sound, at all. Now, I do know what the sound seems like because I remember hearing it once I was younger. So, what I even have to try to to is I even have to seem for any scene where I'm explained a CRT then I can actually dump a high pitched filter within the re in the editing process to hopefully reduce or remove that sound. But, here's the thing. When I'm through with a video, I typically watch it two or 3 times trying to find spelling mistakes, otherwise you know anything wrong with like where something needs color correction

or something like that and that i can see those things most of the time.

But, I literally can't hear the high pitched whine so if I've missed it then I've just missed it. So, all I can do is apologize for that, hopefully I got it beat this video, I tried. went back like 3 times and verified every clip that features a CRT in it.

I put the filter on there. Sometimes the filter doesn't always work too. I'm unsure why, but I've been told sometimes they will still hear it even once I know I've put the filter on there. So, I hope I got it all out, maybe I didn't.

Anyway, I ’ll apologize for it properly.

And, I anticipate to presenting the complete documentary on this computer.

It ’s a very fascinating piece of computer history.

Until then, stick around and thanks for watching!

This is something very useful when we have some incomprehensible error that doesn't usually happen because thanks to idm crack we'll instantly know what the problem is.

ReplyDelete